charpy impact test simulation|charpy impact test pdf : wholesaler The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related .

WEBModel: Luana Dias @LuannaDevil . 22 Jan 2023 05:30:17

{plog:ftitle_list}

Resultado da Manuella Lapa | 29/09/2023. Peglow - Sport. O Sport ficou apenas no empate com o Avaí por 2 x 2, na Ressacada, pela Série B. O Leão da Ilha .

This work emphasizes the modeling and simulation of Charpy impact test to evaluate fracture energy at different pendulum velocities of armor maraging steel 300 using .Charpy Impact Test. To find the impact resistance of mild steel.

Experimental investigations have been carried out to assess the impact strengths of both of these self-healing Al6061 composites using Charpy impact test.In this exercise you will perform a simulated Charpy impact test and plot the change in impact energy as the test temperature changes and link this data to the ductile/brittle transition in steels. Charpy impact test has been simulated using Johnson-cook plastic material model with damage. This video takes you through critical steps such as defining Johnson cook material model, geometry.

The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related .work presents the finite element modeling and simulation of V-notch Charpy impact test over the range of the velocities according Johnson and Cook (J-C) model using Abaqus software.

The aim of our work was to develop 2D and 3D models for FEM simulation of the impact test for different loading conditions, to check the calculated results using experimental data, and to .

Studying the step-by-step evolution of failure of polymeric sample allows for establishing stages of the process characterising the Charpy impact, pointing out processes and phenomena that. Simulation helps identifying the stages of the material failure. Using the bilinear hardening model for the polymer failure at low impact velocity (1.3 m/s) gave reasonable simulations. The time for failure process is longer at lower speed and the aspect of the failed surface depends on the impact velocity.paper, the geometry of standard Charpy impact test is designed. Specimens with dierent widths and side grooves are tested. The nite element model of Charpy impact was established by ABAQUS software. Use test results and simulation results to verify each other. The eects of sample width, side groove depth and side groove bot -

This work emphasizes the modeling and simulation of Charpy impact test to evaluate fracture energy at different pendulum velocities of armor maraging steel 300 using ABAQUS. To evaluate the fracture energy, V-notch specimen is fractured using the Johnson and Cook Damage model. The Charpy impact tests are of great importance related to fracture .

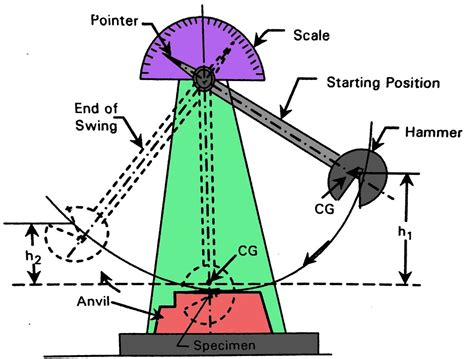

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . The calculated Charpy impact energy was 482.80 J which was very close to experimental value of 485.43 J, as shown in Table 2. Additionally the contours of the stress triaxility ahead of the growing crack front from the Charpy impact test simulation is shown in Fig. 8 (c). The contours of the stress triaxiality from 1.0 to 1.4 are shown. Numerical simulation of impact test3.3.1. Impact sample modeling. . The entire Charpy impact test model was simplified as a hammer with a mass of 6.25 kg impacting the composites. And the kinetic energy of the impact tester (JB-50, China) at the moment of impact was exactly 50 J.Learn more about Charpy & Izod Testing. Drop Weight Impact Test. A second method was to drop a weight in a vertical direction, with a tube or rails to guide it during the "free fall." Once again, with the height and weight known, impact energy can be calculated. . These factors make falling weight testing a better simulation of functional .

What Is the Charpy Impact Test? The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, the test calculates energy absorption based on the pendulum’s height before and after passing .

ASTM D256 and its equivalent ISO 180 recommend Izod as the standard testing method over Charpy for low-velocity impact testing (Raj et al. Citation 2021). For high-velocity impact testing, the damaging surface is more localised, so the structural response is less important, and therefore equal dimensioning is not relevant. Charpy impact test is a low cost but reliable test that breaks a notch specimen under impact loading using a . The study provided a reliable numerical model to predict the Aluminum 6061 behaviour under high rate impact loading conditions. The simulation-based tool can be used to design any related applications. The study utilized Johnson . The simulation and optimisation of the Charpy impact test can simplify experimental processes and improve experimental accuracy [12]. The ability of a material to absorb energy during elastic .

This work emphasizes the modeling and simulation of Charpy impact test to evaluate fracture energy at different pendulum velocities of armor maraging steel 300 using ABAQUS. To evaluate the fracture energy, V-notch specimen is fractured using the Johnson and Cook Damage model. The Charpy impact tests are of great importance related to fracture .

Charpy test is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's toughness and acts as a tool to study temperature-dependent brittle-ductile transition. The Major objective of the analysis is to estimate the resilience of Pressure plate ear when subjected to .

Charpy Impact Test. Aim Theory Procedure Self Evaluation Simulation Assignment Quiz Videos References Feedback Charpy Impact Test . Download from http://expertfea.com/solvedFEA8.htmlWe offer high quality ANSYS tutorials and Finite Element Analysis solved cases for Mechanical Engineering.I.Download Table | Comparison of Charpy test results between experiment and simulation. from publication: Flow and fracture behavior of aluminum alloy 6082-T6 at different tensile strain rates and .

This simulation shows the impact testing to calculate the resilience of materials. The Izod testing has been simulated with V-notched sample. A sensitivity s.Explain how the specimen will be placed in charpy impact test? Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs Contact Us Phone: General Information: 011-26582050 Email: [email protected] impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its behavior under sudden loading. This test is crucial in assessing the suitability of materials for applications .

To find the impact resistance of mild steel and cast iron. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . where it was found that the numerical simulation slightly over predicted the time by around 10%. Fig. 16.A very thorough study has been highlighted on investigating the effects of various factors on the Charpy impact test of X80 steel. This includes controversial factors such as pendulum speed and sample width, which have been chosen for analysis. . Dasari M, Chand S, Ganesh S, Saibhargavi U (2018) Modeling and simulation of Charpy impact test .

charpy impact test sample

and deformation paths in V-notch and Charpy impact tests for 340R 4 CHARPY IMPACT TEST The Charpy V-notch impact test was carried out based on KSB 0810-2003 to determine the impact performance of the three steel sheets. During the Charpy impact test, the maximum velocity of the falling pendulum is 5.4m/sec, which have a total kinetic energy of .

I want to determine the impact energy absorbed by epoxy sample in Izod and Charpy impact test by simulating the impact tests in ANSYS workbench v12. I am having the experimental values for same. View Many engineers were interested in Charpy test for metallic materials [11,28,29,30], but nowadays this test, in classical or modified configuration, becomes useful to be done for other materials, including polymers, composites [], and ceramics [].Simulation of such a test is useful for understanding the material behavior under impact load, and when knowing .Simulation Description In this exercise you will perform a simulated Charpy impact test and plot the change in impact energy as the test temperature changes and link this data to the ductile/brittle transition in steels.

Ireland, D. R. (1976) Critical review of instrumented impact testing, Conf on Dynamic Fracture Toughness, London, 47–61. Google Scholar Kalthoff, J. F., Winkler, S. and Böhme, W. (1985) A novel procedure for measuring the impact fracture toughness KId with precracked Charpy specimens, Journal de Physique, C5 No. 8, 279–286.

can convenience sampling be used in quantitative research

can i use purposive sampling in quantitative research

Resultado da O UniBRASÍLIA EaD pertence ao Ecossistema Brasília Educacional e oferta cursos de graduação nas modalidades, semipresencial e 100% digital.

charpy impact test simulation|charpy impact test pdf